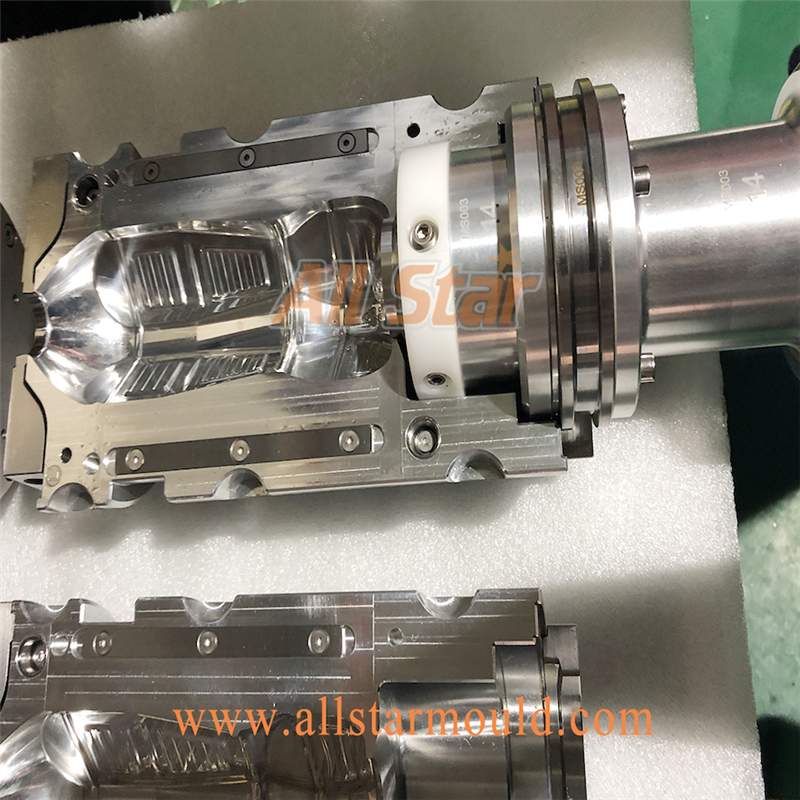

Blowing Molds For Plastic Bottles

Polyethylene Terephthalate (PET) is a non-porous thermosetting plastic that is perfect for manufacturing anything that needs to be water-tight. PET is a popular choice for drinks bottles because it is lightweight, safe and fully recyclable.

The PET bottle blow moulding process works by reheating a pre-moulded PET preform which is then automatically positioned into a mould. High pressure food grade compressed air is then injected into the preform which expands to form the shape of the mould. Once the plastic has cooled, the bottle is removed and the process repeats.

PET bottle molds construction is simple compare with other plastic molds,we will combine character of your bottle and technical control well with our professional skill in plastic bottle preform design, so that your bottles can distinguish themselves to attract more customers.

Good bottle blowing mould design skill can help you reduce cost. We will help you reduce weight (save PET material ) and even strengthen bottle and increase leak-proofness meanwhile.

Crafted with the latest technology and expertise, our PET bottle blow mold ensures consistent and uniform bottle production, resulting in a flawless finish every time. Whether you are in the beverage, pharmaceutical, or personal care industry, our blowing molds are versatile and adaptable to meet your specific bottle design requirements.

Our blowing molds are meticulously designed to accommodate various bottle sizes and shapes, offering flexibility and customization to suit your unique packaging needs. With a focus on efficiency and productivity, our molds are engineered to optimize production processes, reducing downtime and maximizing output.