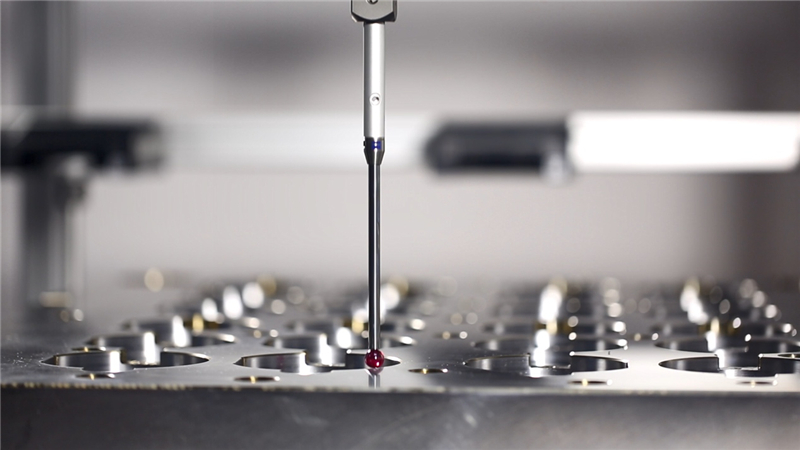

Quality Control

ALL STAR PLAST has made its own perfect production and management system. There are strict quality control managements in each process. We try our best to avoid mistakes, and put an end to extend mistake to the next process.Its ranges from design analysis and inspection of plastic products to the research on design feasibility of mold, from material purchasing to quality inspection of material, from processing technic selection and arrangement to quality inspection, from mold assembling and installation to mold test,etc..For each process, there are homologous table and quality inspection standard. Each link should be ensured without defect, and then we can keep the delivered molds qualified.